About

Why choose us

We are a professional Nov Mission pump supplier in China, foucing on manufacturing & supplying high quality pumps and service for oil and gas drilling, mining, and fluid pumping industry . Our pumps are specifically designed to meet the needs and challenges of some of the most demanding industries, including horizontal directional drilling and well stimulation fracking.

With more than 15 years of experience, our engineers are constantly striving to improve the durability and efficiency of the pumps and pump parts, and engineering service. we create value for our customers by offering a one stop pumping solution for oilfeild soild control system equipment. We provide you with innovations that will help you to operate more efficiently and save money.

We offers a complete line of centrifugal sand pumps to suit for all kinds of drilling application. Size ranges from 3x2x13, 4x3x13, 5x4x14, 6x5x11,6x5x14, 8x6x11,8x6x14, 10x8x14, 12x10x23 to 14x12x22. Bare pumps, matching motors are available from 7.5KW to 90KW, with rotation 800, 1000, 1150,1450, 1750 to 3500 RPM at 50Hz or 60Hz.

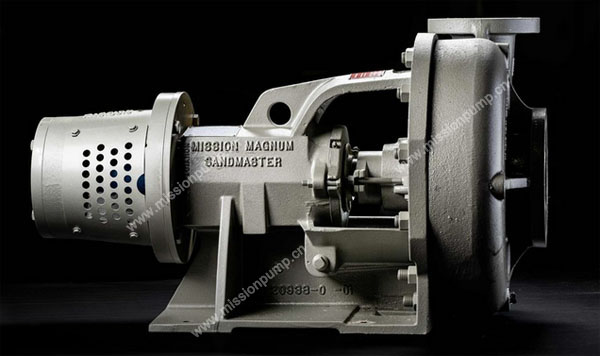

The model 10x8x14 and 8x6x14 centrifugal magnum pump used on solid control system over 3000 meter-long drilling rigs with big viscosity and heavy specific gravity drilling fluid. 8x6x11 centrifugal mud solid control feeding pump applies to under 3000 meter-long drilling rigs, and it also can be used to supply mud to triplex mud pump as a filling pump. 6x5x11 centrifugal pump applies to truck-mounted drilling rigs or pocket drilling rigs. 4x3x13 drilling centrifugal pump is usually used as measuring pump or replenishment pump. 3x2x13 model pump is usually used as clean water pump.

The magnum XP pump is designed for pumping high volumes of abrasive and corrosive slurries. The 12x10x23 and 14x12x22 model are very popular on oil and gas fracking opertion as blender pump. It is used in hydraulic fracturing process, fluids carrying proppant are pumped into the ground with enough pressure to crack the rock. The proppant is left behind to hold open the cracks, while the fluid is flowed back allowing oil and gas the ability to flow to surface. Our technical engineers use advanced manufacturing technologies and material sciences to extend the service life of single stage centrifugal pumps that handle abrasive slurries with high sand content, with more long life time and higher efficiency.

The MISSION centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud. This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications.

Our Services

best resources we have

More than three medium-sized foundries cooperate with us.

best effort we provide

Every piece must be inspected, and the delivery period is guaranteed.

best services & solutions

One year warranty and One-to-one after-sales service & solutions.

provide personalized services

Design,drawing,casting,Machining, technical service and confidentiality only for you.

oem casting services

We offer the drawing & casting services follow the parts model or 3D drawing

lot of stock service

Lot of mission pump parts in stock ,can ship immediately when get the payment.